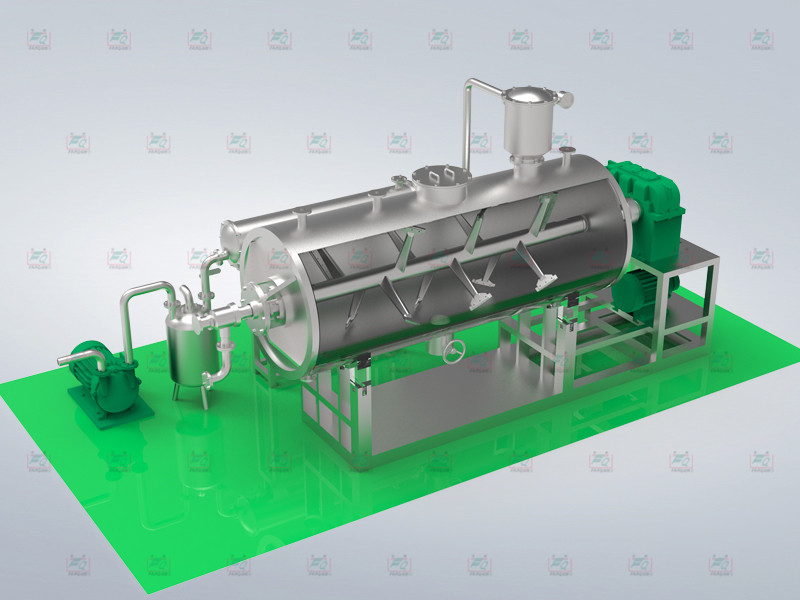

ZB vacuum harrow drying equipment is a novel horizontal intermittent vacuum drying equipment, wet materials evaporate by conduction, with scraper agitator constantly removes the material on the hot surface and pushes to form a circulating flow in the container, water evaporation is pumped out by vacuum pump.

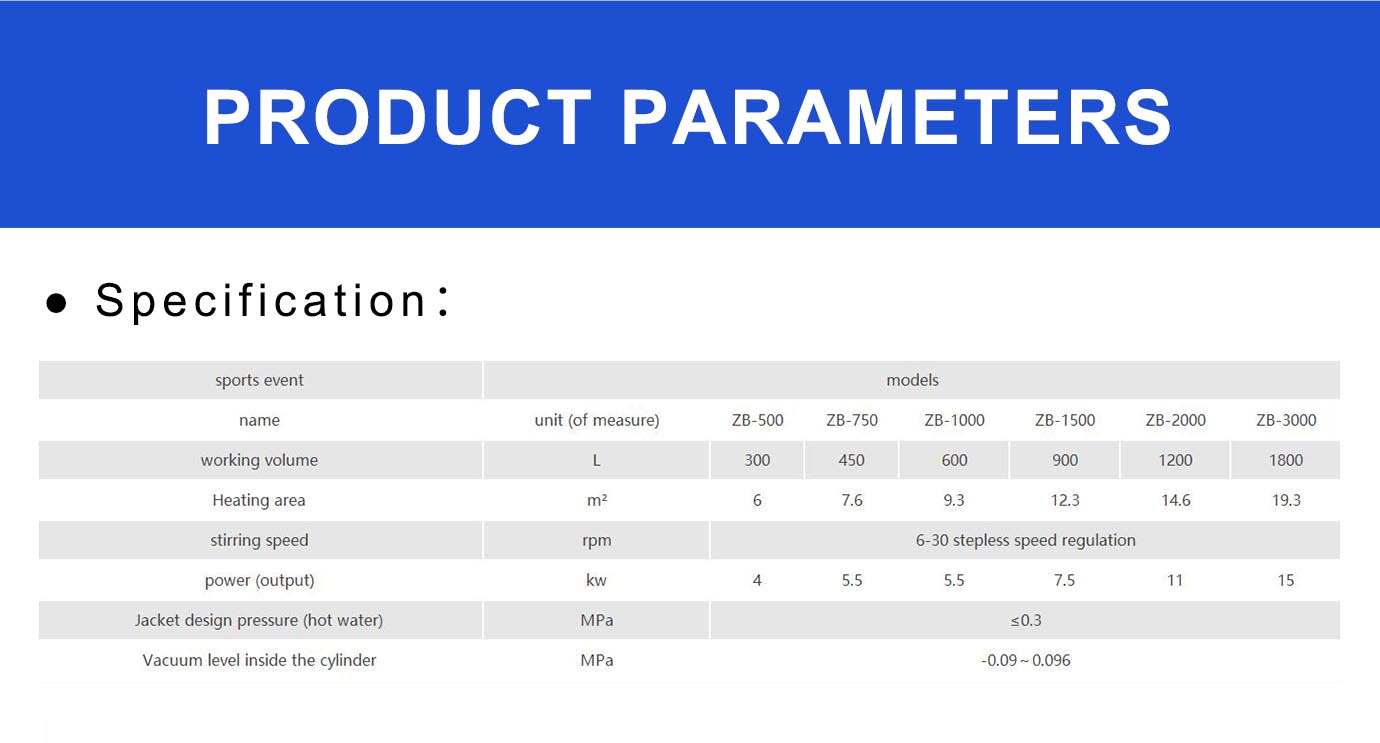

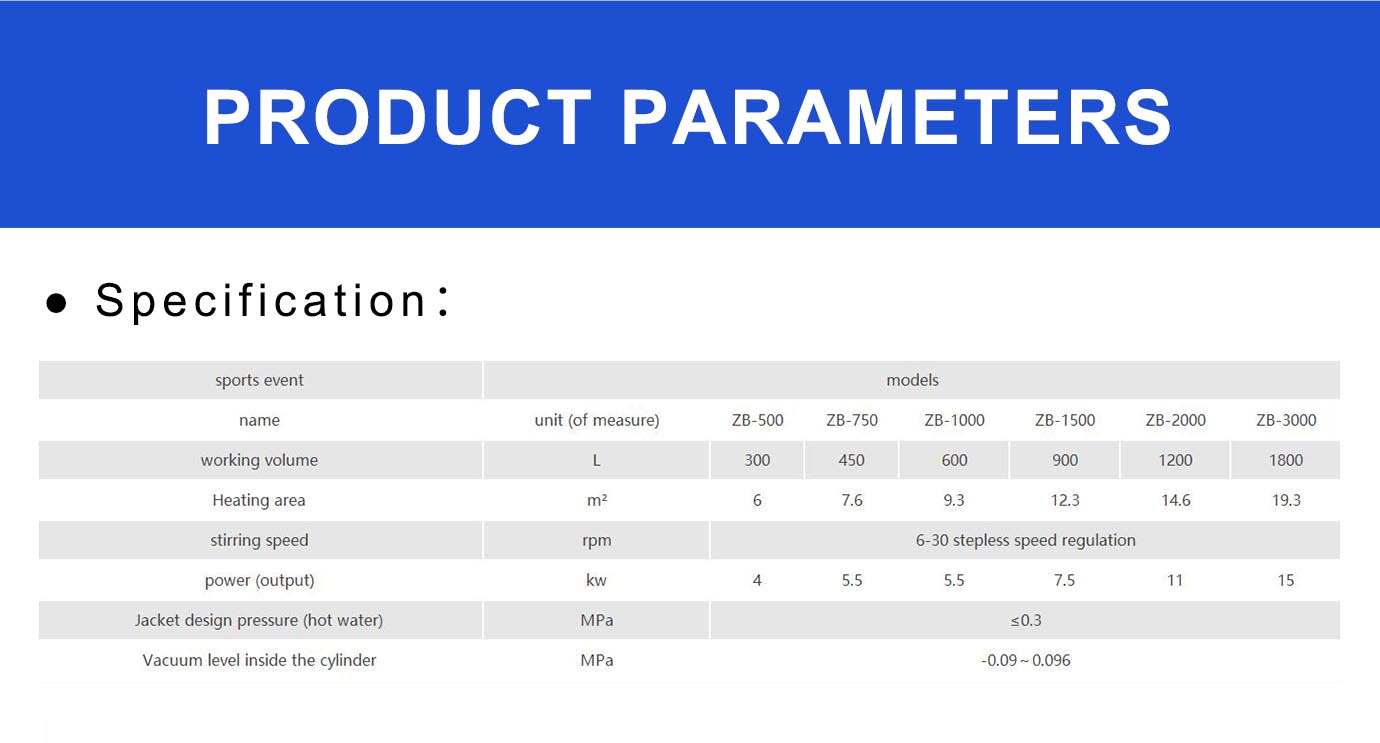

| sports event | models |

| name | unit (of measure) | ZB-500 | ZB-750 | ZB-1000 | ZB-1500 | ZB-2000 | ZB-3000 |

| working volume | L | 300 | 450 | 600 | 900 | 1200 | 1800 |

| Heating area | m² | 6 | 7.6 | 9.3 | 12.3 | 14.6 | 19.3 |

| stirring speed | rpm | 6-30 stepless speed regulation |

| power (output) | kw | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 |

| Jacket design pressure (hot water) | MPa | ≤0.3 |

| Vacuum level inside the cylinder | MPa | -0.09~0.096 |

Note: The amount of water evaporated is related to the characteristics of the material and the hot inlet and outlet temperatures.With the continuous updating of products, the relevant parameters will be changed without prior notice.

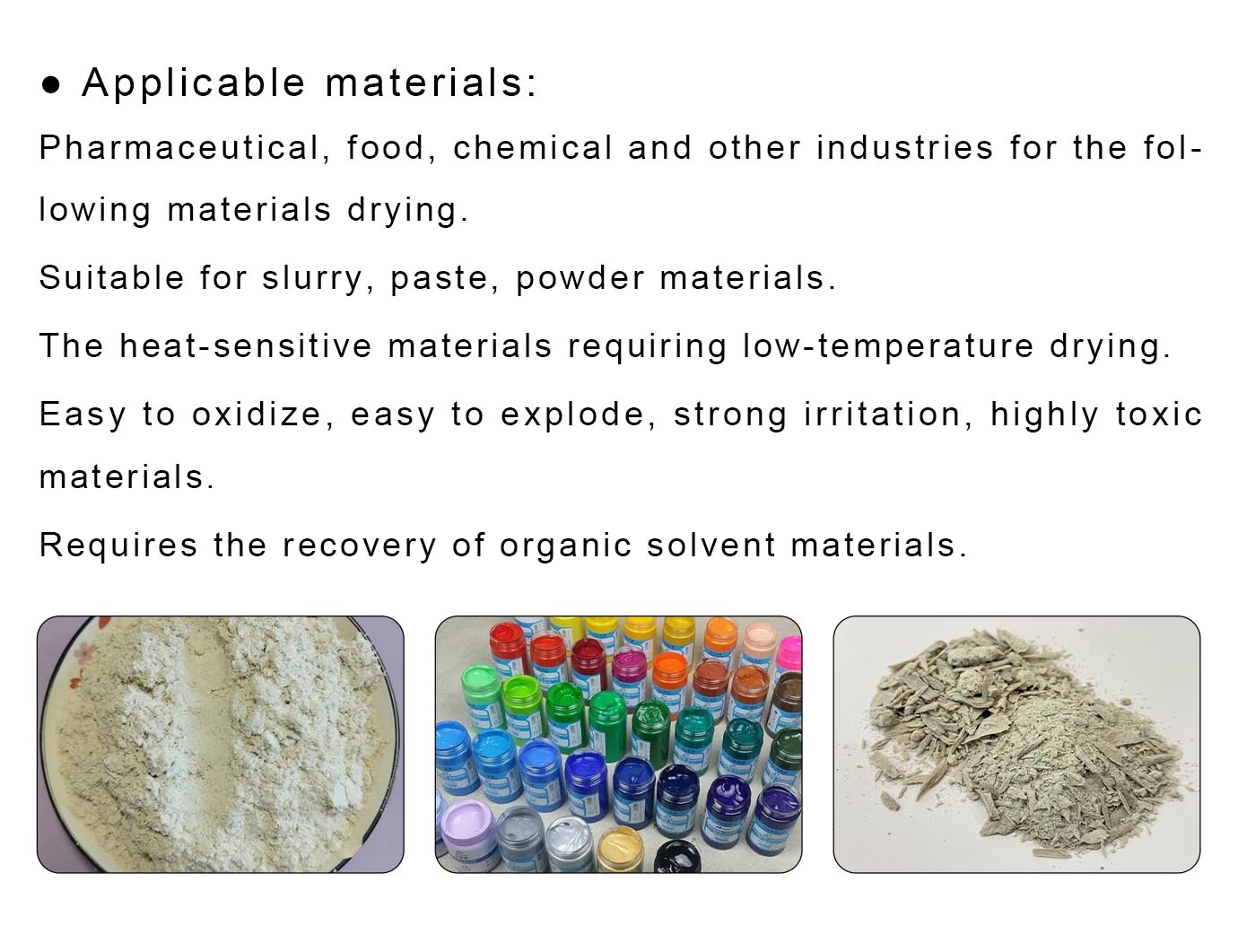

Applicable materials:Pharmaceutical, food, chemical and other industries for the fol.lowing materials drying.

Suitable for slurry,paste, powder materialsThe heat-sensitive materials requiring low-temperature dryingEasy to oxidize,easy to explode, strong irritation, highly toxicmaterials.

Requires the recovery of organic solvent materials

Jiangsu Fanqun Drying Firm Equipment Factory Co., Ltd. products sell well all over the country, exported to the United States, Japan and Southeast Asian countries, welcomed by domestic and foreign users, the market reputation is excellent, but also China's drying equipment in the professional manufacturer of larger, more varieties of better quality of enterprises.

Complete scientific and quality system Professional technical team and superb technology Sophisticated production equipment

The company has large laser cutting machine, large water cutting machine, large plasma cutting machine, large automatic welding machine, non-destructive testing, mass spectrometer planer, bending machine, shearing machine and other high-end manufacturing and processing and inspection equipment.

Perfect after-sales service system

Pre-sales services :To provide you with project design, process design, suitable for your machine and equipment selection program development, according to your special needs, design and manufacture of products, for your training of technical operators.

Services during sale :Accompany you through the acceptance of the equipment and assist in the development of construction plans and detailed procedures.

After-sales service :The company sends technicians to the site to guide equipment installation commissioning site and training operators.

Vacuum Harrow Drying Equipment,rake dryer,rake drying equipment,rake dryer manufacturer