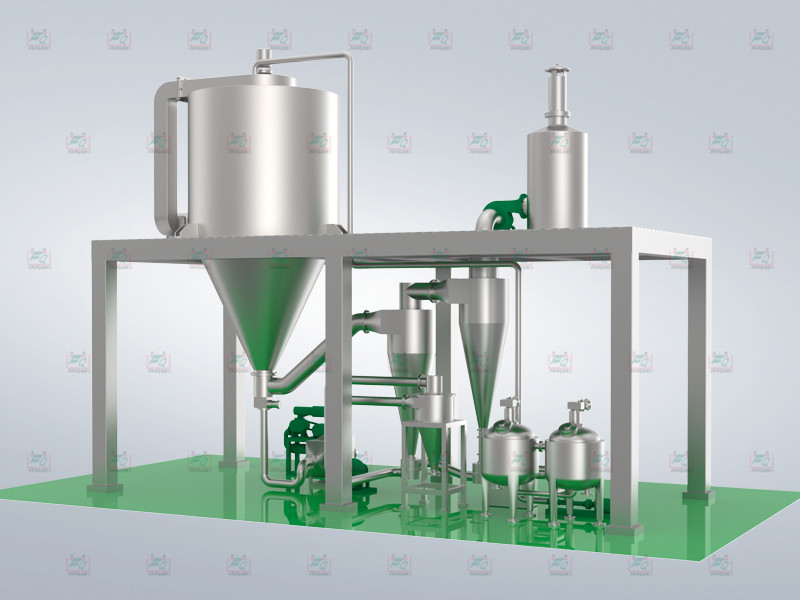

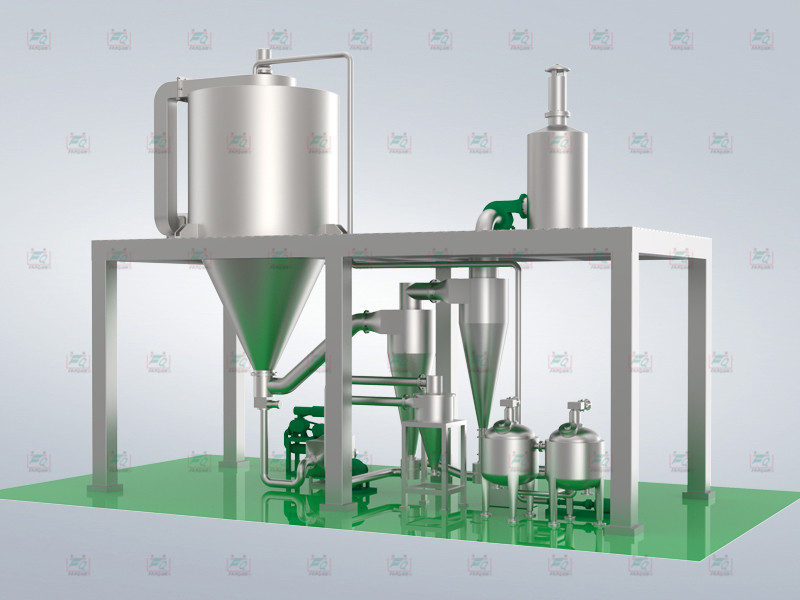

Fanqun Spray Dryer transforms liquid solutions into free-flowing powders with precision. Equipped with a high-pressure atomization system and PLC-controlled temperature settings, it ensures rapid evaporation while preserving heat-sensitive materials. Ideal for pharmaceuticals, food additives, and ceramics, our spray drying equipment feature 316L stainless steel construction, achieving ≤0.5% residual moisture. Customizable configurations (centrifugal/nozzle) and energy recovery systems reduce operating costs by 25%.

Key Features:

- Capacity: 50L/h to 5,000L/h

- Applications: Milk powder, enzymes, dyes, and polymer microspheres

- Certifications: CE, ISO 9001

The spray drying equipment series of Jiangsu Fanqun Drying Equipment Factory Co., Ltd. includes high-speed centrifugal spray dryer, pressure spray dryer, and spray drying machine for Chinese herbal extracts

Global Spray Dryer Solutions | Drying Systems for Different Industries

Energy-Efficient, Customized Drying Equipment for Food, Chemicals, Pharmaceuticals & Agriculture –

Trusted by 300+ Clients Worldwide

Spray Drying Equipment -

Drying Solutions for Multiple Industries

Food industry Fast drying of heat-sensitive materials (e.g. milk powder, coffee), retaining nutrients and flavour, extending shelf life.

|

Pharmaceutical industry Preparation of easy-to-dissolve, homogeneous drug particles or powders to improve drug stability and bioavailability. |

Chemical industry Production of high-purity chemical products (e.g. dyes, catalysts), to ensure particle uniformity and chemical stability. |

Ceramic materials Preparation of ceramic powders with good flowability, improving sintering efficiency and finished product performance. |

Biotechnology Dry microorganisms, enzymes and other active substances to maintain their biological activity and extend storage time. |

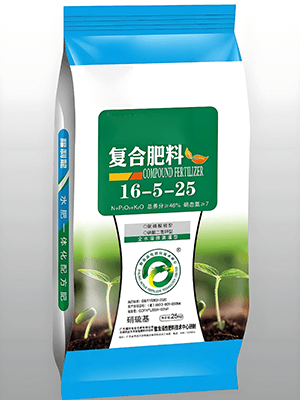

Agriculture Production of soluble pesticide or fertiliser granules to achieve slow release effect and reduce transport costs. |

Daily chemical industry Manufacture detergent and cosmetic powders (e.g. talcum powder) to enhance solubility and ease of use. |

New energy materials Preparation of cathode materials for lithium batteries, etc. Precise control of particle microstructure to optimise electrochemical performance. |

and 95%-98% of the water can be evaporated instantly in the hot air stream, and the drying time takes only a fewseconds, especially suitable for drying heat-sensitive materials. | |

Advantages Of Our Spray Dryers |

|

For the moisture content of 40-60% (special materials up to 90%) of the liquid can be dried into powder products, drying without crushing and screening, reduce production processes, improve product purity. The product particle size, bulk density, moisture, within a certain range can be adjusted by changing the operating conditions, control and management are very convenient. |

Thank them for their trust

Long-term partner of the world's and China's top 500 companies

| | | | |

| | | | |

Tailor-Made Journey for Your Spray Drying Solution

Stage 1 | Precision Collaboration Workshop Carry out double-blind demand in-depth mining: led by senior drying processor, establish customised development matrix model through reverse analysis of material characteristics, energy consumption benchmarking, and historical case benchmarking. |

Stage 2 | Dynamic Thermodynamic Modelling Using multi-physical field coupling simulation technology to construct an exclusive drying dynamics model. Through the visualisation of airflow distribution simulation and heat transfer gradient prediction, the optimal combination of equipment structure parameters can be locked. |

Stage 3 | Lean Manufacturing Quality Chain Implementation of German VDI standard manufacturing protocols: open access to witness key points (e.g. verification of stainless steel welding process, airtightness testing of air ducts), support for customer representatives in modular pre-acceptance test (FAT). |

Stage 4 | Turnkey Integrated Systems Implementation of a ‘Zero Boundary’ delivery programme: including environmental adaptation (altitude/humidity compensation), thermal system balancing commissioning, and operational maintenance sandboxes to ensure production at design capacity. |

Stage 5 | Lifecycle Protection The IoT Remote Operation and Maintenance Centre is enabled to provide dynamic analysis of drying efficiency, preventive maintenance warnings, and process upgrading kit push, building a closed loop of continuous value-added intelligent manufacturing ecology. |

About Us

Jiangsu Fanqun Drying Equipment is a manufacturer of spray dryers,

customising a wide range of drying equipment for the high demands of the food, tobacco, chemical and pharmaceutical industries.

We are Fanqun Drying Equipment Factory | Forty years ago, China's drying equipment field was still blank, Mr Fan Bingxi sowed a seed of innovation in Zhenglu Town, Changzhou. From the first hot air circulation oven to the intelligent drying system, Fanqun drying with craftsmanship as the furnace, science and technology as the flame, quenching the benchmark of national industry.

As a pioneer in the industry, the company has accumulated more than 30 national patents, led the development of centrifugal spray drying tower, intelligent Chinese medicine extract dryer and other milestone products, breakthrough in Europe and the United States technology blockade, and twice undertook the national science and technology research projects. 2002 among the high-tech enterprises in Jiangsu Province, ‘Fanqun brand’ equipment is exported to more than 50 countries. Its ‘Fanqun brand’ equipment is exported to more than 50 countries, and is praised by the American chemical giants for its ‘performance exceeding the European standard’.

In the green wave, Fanqun engraves environmental protection into its genes: sludge resourcing technology helps Southeast Asian cities to reduce pollution, low-carbon hot air furnace reduces emissions by 30%, and agricultural product drying programme drives a billion rural economy. With pressure vessel manufacturing licence and ISO double certification in hand, and a steady AAA grade credit enterprise for 13 consecutive years, Fanqun uses the temperature of drying technology to balance industrial development and ecological harmony.

From the small town of Changzhou to the world stage, Fanqun Drying always takes ‘drying the dignity of Chinese manufacturing’ as its mission, and makes every grain of material sublimation, all of which is the note of the times. |

Drying speed is fast, the surface area of the material is greatly increased after atomisation,

Drying speed is fast, the surface area of the material is greatly increased after atomisation,

The production process is simplified and the operation control is convenient.

The production process is simplified and the operation control is convenient.