Vacuum drying equipment is to heat and dry the material to be dried under vacuum condition. Vacuum Dryer utilizes vacuum pump for pumping and dehumidification, so that the studio is in a vacuum state, the drying rate of the material is greatly accelerated, and also saves energy. Vacuum drying equipment is divided into static drying and dynamic dryer.

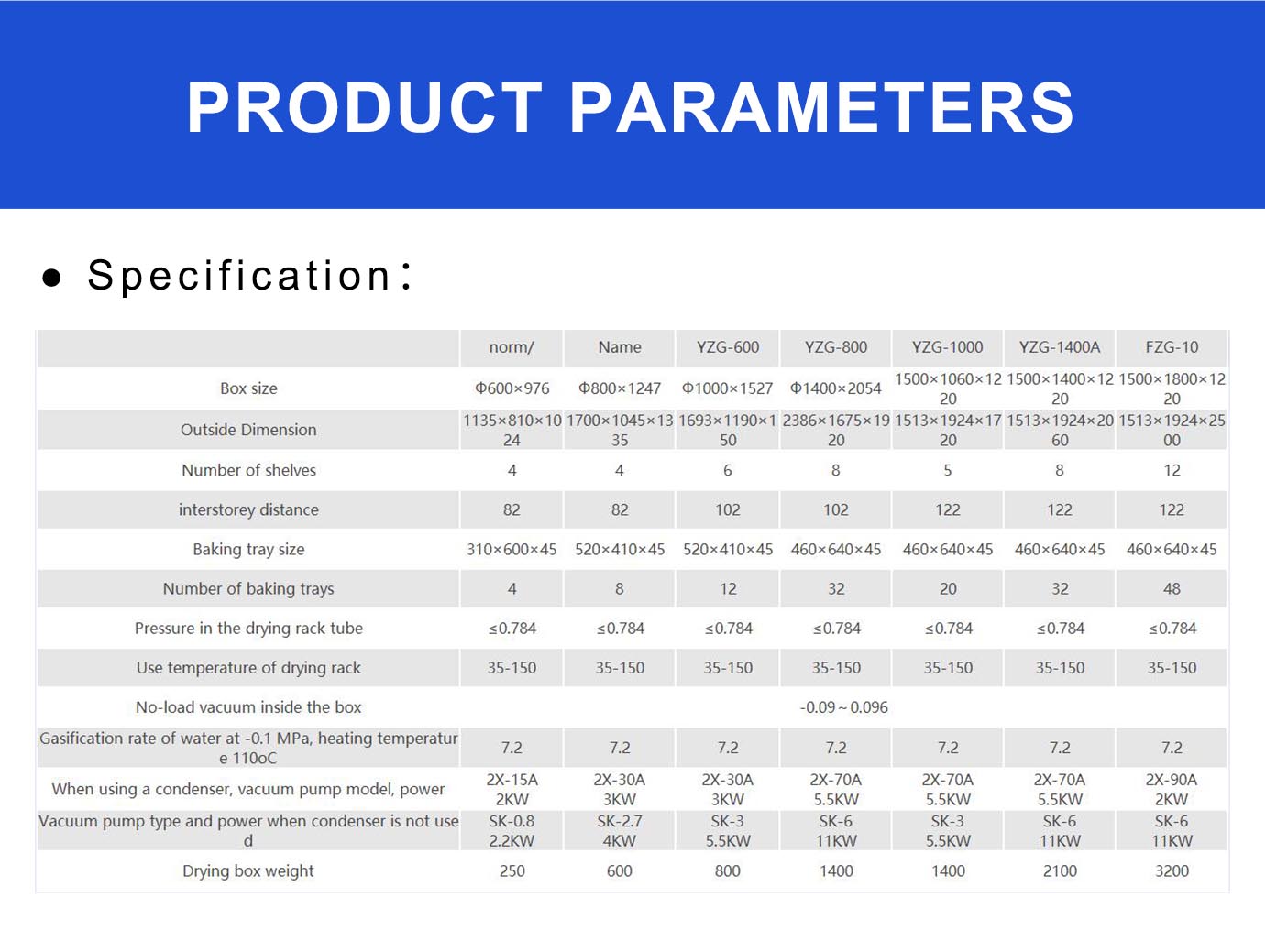

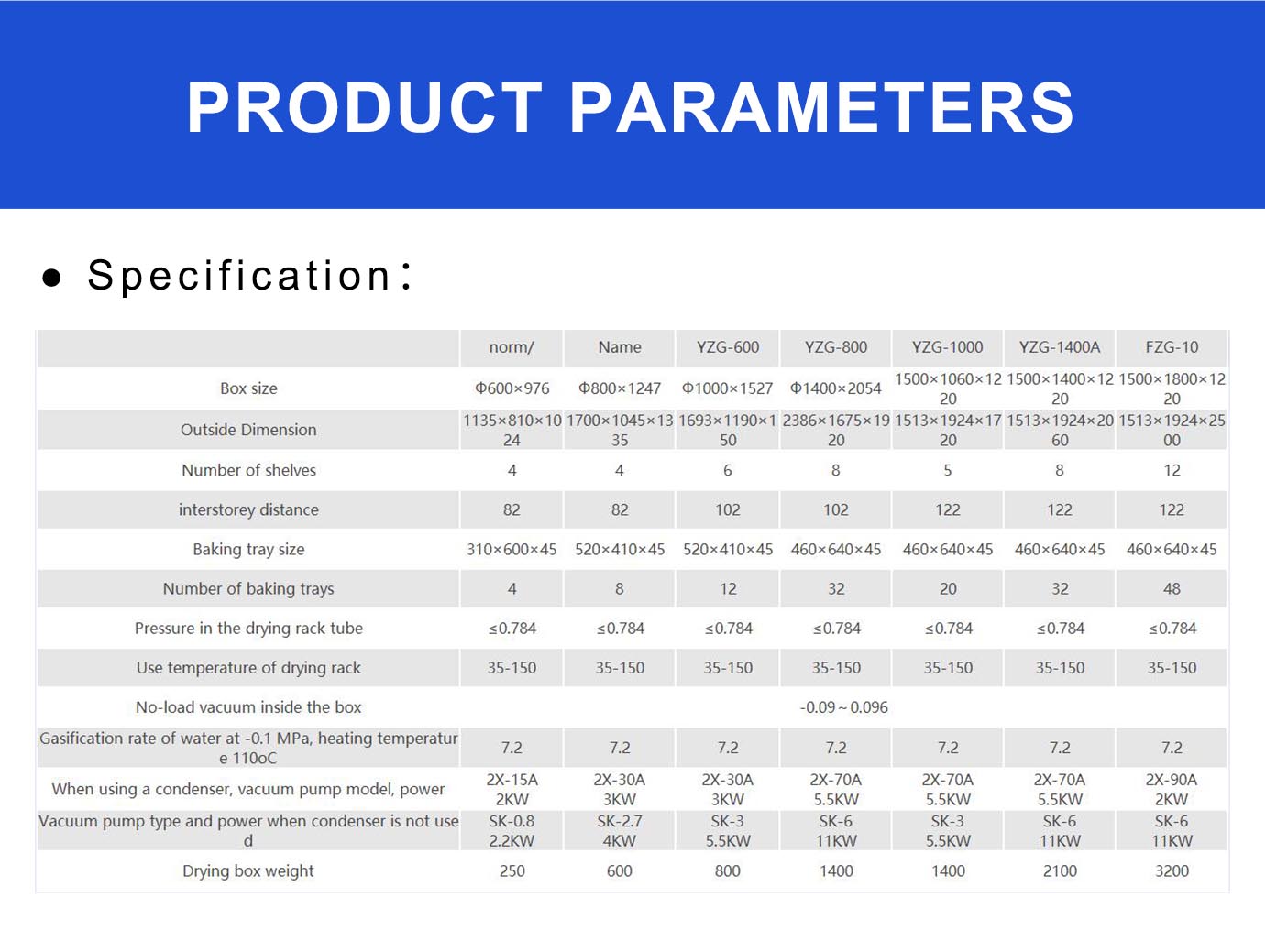

| norm/ | Name | YZG-600 | YZG-800 | YZG-1000 | YZG-1400A | FZG-10 | FZG-15 | FZG-20 |

| Box size | Ф600×976 | Ф800×1247 | Ф1000×1527 | Ф1400×2054 | 1500×1060×1220 | 1500×1400×1220 | 1500×1800×1220 |

| Outside Dimension | 1135×810×1024 | 1700×1045×1335 | 1693×1190×150 | 2386×1675×1920 | 1513×1924×1720 | 1513×1924×2060 | 1513×1924×2500 |

| Number of shelves | 4 | 4 | 6 | 8 | 5 | 8 | 12 |

| interstorey distance | 82 | 82 | 102 | 102 | 122 | 122 | 122 |

| Baking tray size | 310×600×45 | 520×410×45 | 520×410×45 | 460×640×45 | 460×640×45 | 460×640×45 | 460×640×45 |

| Number of baking trays | 4 | 8 | 12 | 32 | 20 | 32 | 48 |

| Pressure in the drying rack tube | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 |

| Use temperature of drying rack | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 |

| No-load vacuum inside the box | -0.09~0.096 |

Gasification rate of water at -0.1 MPa, heating temperature 110oC

| 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| When using a condenser, vacuum pump model, power | 2X-15A

2KW | 2X-30A

3KW | 2X-30A

3KW | 2X-70A

5.5KW | 2X-70A

5.5KW | 2X-70A

5.5KW | 2X-90A

2KW |

| Vacuum pump type and power when condenser is not used | SK-0.8

2.2KW | SK-2.7

4KW | SK-3

5.5KW | SK-6

11KW | SK-3

5.5KW | SK-6

11KW | SK-6

11KW |

| Drying box weight | 250 | 600 | 800 | 1400 | 1400 | 2100 | 3200 |

Note: Water ring vacuum pumps are used in conjunction with mechanical pressurisation to increase the vacuum level.

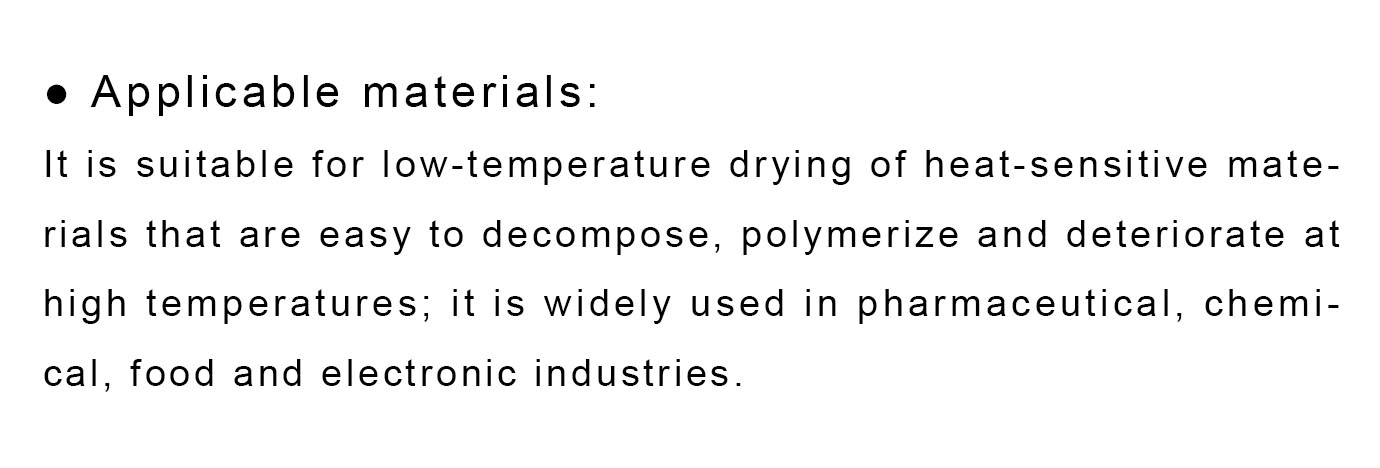

Vacuum Drying equipment is suitable for low-temperature drying of heat-sensitive mate-rials that are easy to decompose, polymerize and deteriorate athigh temperatures; it is widely used in pharmaceutical, chemi.cal, food and electronic industries.

Jiangsu Fanqun Drying Firm Equipment Factory Co., Ltd. products sell well all over the country, exported to the United States, Japan and Southeast Asian countries, welcomed by domestic and foreign users, the market reputation is excellent, but also China's drying equipment in the professional manufacturer of larger, more varieties of better quality of enterprises.

Complete scientific and quality system Professional technical team and superb technology Sophisticated production equipment

The company has large laser cutting machine, large water cutting machine, large plasma cutting machine, large automatic welding machine, non-destructive testing, mass spectrometer planer, bending machine, shearing machine and other high-end manufacturing and processing and inspection equipment.

Perfect after-sales service system

Pre-sales services :To provide you with project design, process design, suitable for your machine and equipment selection program development, according to your special needs, design and manufacture of products, for your training of technical operators.

Services during sale :Accompany you through the acceptance of the equipment and assist in the development of construction plans and detailed procedures.

After-sales service :The company sends technicians to the site to guide equipment installation commissioning site and training operators.

Vacuum Dryer,Vacuum Dryer manufacturer,Vacuum Drying equipment