FL, FG Series Vertical Boiling Granulator Dryer is based on the principle that the material powder particles, in the raw material container (fluidized bed) in a circular state of fluidization, by the purified heated air preheating and mixing, the binder solution will be sprayed into the atomization of a number of particles aggregated into agglomerates containing the binder.

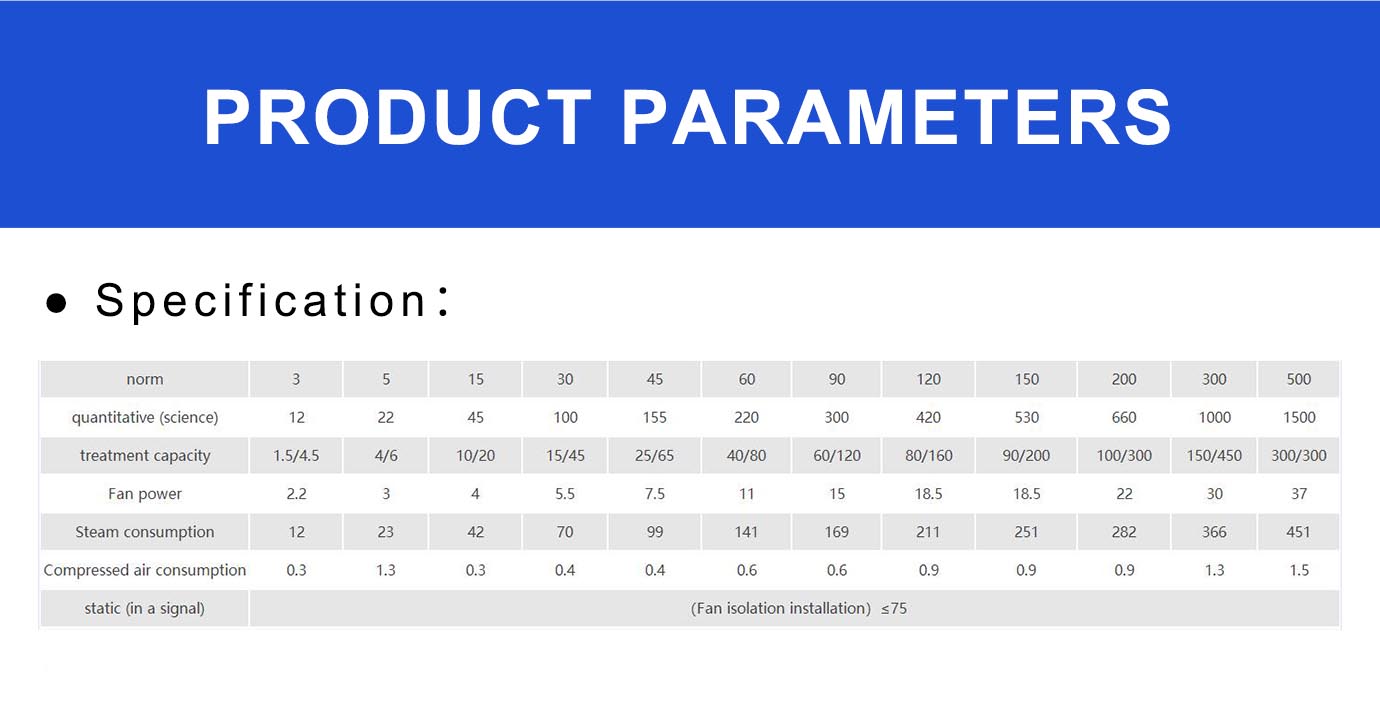

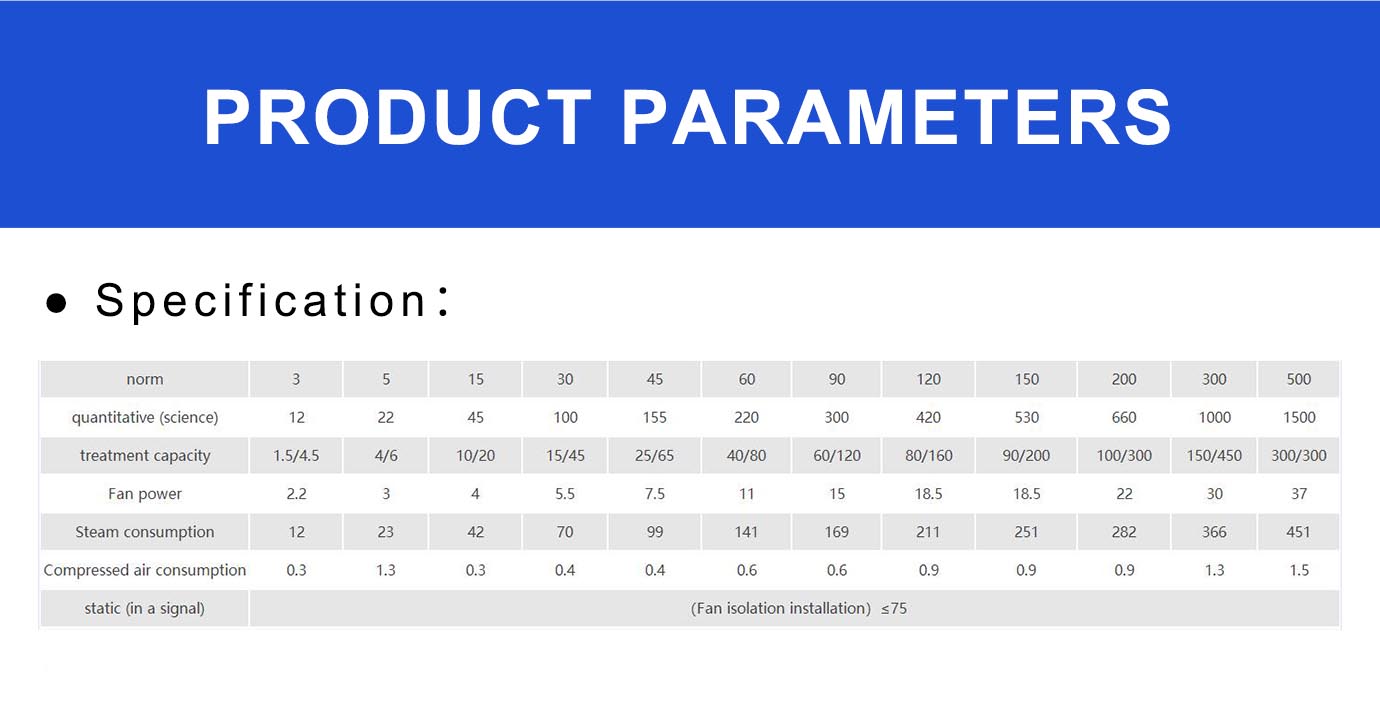

norm | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 |

| quantitative (science) | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 530 | 660 | 1000 | 1500 |

| treatment capacity | 1.5/4.5 | 4/6 | 10/20 | 15/45 | 25/65 | 40/80 | 60/120 | 80/160 | 90/200 | 100/300 | 150/450 | 300/300 |

| Fan power | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 37 |

| Steam consumption | 12 | 23 | 42 | 70 | 99 | 141 | 169 | 211 | 251 | 282 | 366 | 451 |

| Compressed air consumption | 0.3 | 1.3 | 0.3 | 0.4 | 0.4 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.3 | 1.5 |

| static (in a signal) | (Fan isolation installation)≤75 |

| Overall dimensions | 1.0×0.55×1.8 | 1.2×0.6×2.1 | 1.25×0.9×2.1 | 1.6×0.9×2.3 | 1.65×1.1×2.4 | 1.85×1.25×3 | 1.85×1.25×3 | 2.2×1.65×3.1 | 2.27×1.72×3.1 | 2.34×1.9×3.5 | 2.8×1.9×3.8 | 3×2.55×4.2 |

Note: FG without granulation section

1.Pharmaceutical granulation and coatingGranulation: granules for tablets, granules for punch, granulesfor capsules.

Coating:granule,pill protective layer, color preparation, slowrelease,film,enteric coating

2.Food granulation and coatingSugar,coffee,cocoa powder,cream,powdered juice, aminoacid, seasoning, puffed food.

3.Pesticide, pigment coloring, dye granulation.

4.Drying of powder, granule and block materials.

Jiangsu Fanqun Drying Firm Equipment Factory Co., Ltd. products sell well all over the country, exported to the United States, Japan and Southeast Asian countries, welcomed by domestic and foreign users, the market reputation is excellent, but also China's drying equipment in the professional manufacturer of larger, more varieties of better quality of enterprises.

Complete scientific and quality system Professional technical team and superb technology Sophisticated production equipment

The company has large laser cutting machine, large water cutting machine, large plasma cutting machine, large automatic welding machine, non-destructive testing, mass spectrometer planer, bending machine, shearing machine and other high-end manufacturing and processing and inspection equipment.

Perfect after-sales service system

Pre-sales services :To provide you with project design, process design, suitable for your machine and equipment selection program development, according to your special needs, design and manufacture of products, for your training of technical operators.

Services during sale :Accompany you through the acceptance of the equipment and assist in the development of construction plans and detailed procedures.

After-sales service :The company sends technicians to the site to guide equipment installation commissioning site and training operators.

Boiling Granulating Dryer,Boiling Granulating Dryer manufacturer,Boiling Granulating Drying equipment