Closed-circuit belt dryer process description

Pharmaceutical dregs (sludge) concentrate treatment in the traditional treatment process are used to deal with direct drying methods, such as spray drying, drum scraper drying or direct drying of the filter cake after filtering, such as paddle dryer drying, rotary kiln drying, air drying, flash drying, or belt drying equipment drying, the above methods of treatment in the drying process are produced a large number of organic substances containing wet exhaust and emissions into the atmosphere. These are not in line with environmental protection requirements, if the treatment of these exhaust gases require a large amount of energy consumption and equipment investment, and in all aspects are open or semi-closed operation, can not be achieved in a continuous closed operation, in all aspects of the leakage (leakage of materials, leakage of powder, leakage of gas, leakage of water, etc.), and does not meet the energy-saving environmental protection requirements.

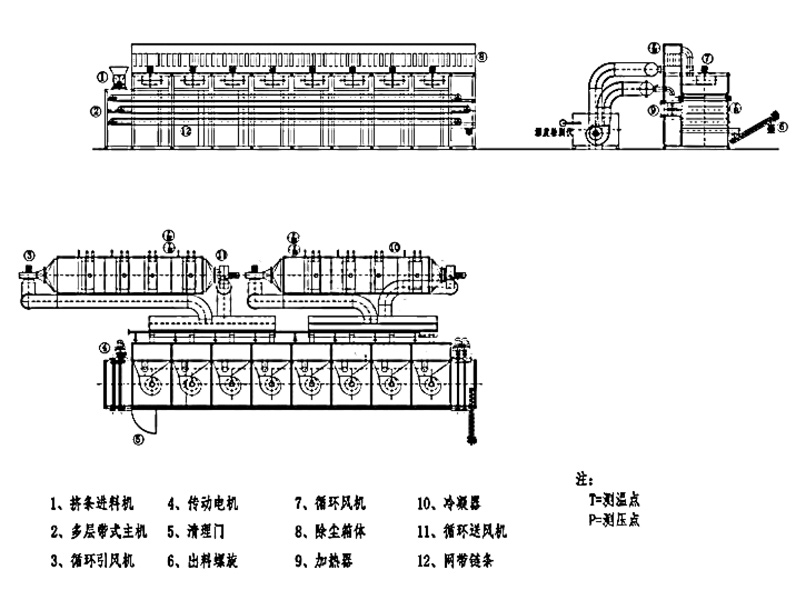

According to the material characteristics, processing requirements, environmental protection requirements, after years of process modification, process exploration and experience accumulation, we have designed a new set of processing technology: that is, the use of closed stacked-screw machine continuous pressure filtration of concentrate into the closed continuous extruder granulator granulation directly into the closed-loop belt dryer drying, closed-loop belt dryer drying finished products are directly used in the closed screw conveyor conveyor to the Packing bag. The closed-circuit belt dryer can adopt low-temperature heat pump type full-circulation multi-layer belt dryer or medium-temperature closed-circuit multi-layer belt dryer. The whole process is carried out in sealed process, which can ensure that the whole process has no gas emission, no dust leakage and reliable equipment connection, compact equipment arrangement, simple production process, small footprint, low equipment investment, energy saving and environmental protection.

Closed Circuit Belt Dryer Process Flow Chart

Closed-circuit belt dryer product performance characteristics

1、It can fully realize the treatment of sludge with “reduction, stabilization, harmlessness and resourcefulness”, and the final sludge particles can be used as fertilizer, fuel, incineration, building materials, biofuel, landfill mulch, land use, etc.

2、Adopting continuous mesh belt drying mode, it is suitable for all types of sludge drying system (including sludge with large sand content), with long service life.

3、It can dry 80% water content sludge cake into 10% water content sludge particles; sludge reduction capacity is 1/4-1/5, and the calorific value of sludge after urban sludge drying can reach 3000kcal/kg.

4, low-temperature (40-75 ℃) fully closed drying process, no tail gas emission, no need for odor treatment system; low-temperature drying can fully avoid the volatilization of different types of organic matter in sludge, to avoid the volatilization of malodorous gases, will not cause secondary environmental pollution.

5、System operation safety, no explosion potential danger, no need to flush nitrogen operation; sludge drying process oxygen content <12%, dust concentration <60g/m³, particle temperature <70 ℃, the whole drying process without dust (air flow <2m/s).

6、Transmission speed of mesh belt is controlled by frequency conversion, and water content of sludge discharge is adjustable (10-30%), which meets the requirements of various types of processes.

7、Using ^ heat pump dehumidification technology, comprehensive power consumption 240kw.h/1t.H₂0 (standard)

8, the equipment covers an area of small, easy to install; each evaporation of 1000kg of water equipment covers an area of about 3.5m².

9, using PLC + touch screen control system, fully automatic operation, easy to operate and manage; dry and wet ball temperature and humidity control, feed frequency control, molding control, out of the material solid content control, laying control, manual control.

Scope of application

Closed loop belt dryer can be used for industrial hazardous waste sludge and related materials, including: electroplating sludge, leather sludge, biochemical sludge, petrochemical sludge, pharmaceutical sludge, pesticide sludge, feed sludge, biological agents, pet feed, pet snacks, nickel-containing sludge, copper-containing sludge, lead-containing sludge, tin-containing sludge, heavy metal-containing sludge, chromium-containing sludge, cadmium-containing sludge, hospital clinical waste wastewater treatment sludge, Pesticide wastewater treatment sludge, wood preservation wastewater treatment sludge, cyanide-containing sludge, sludge-like strippings from alkali or organic solvent cleaning of tonic equipment, waste packaging wastewater treatment sludge containing residues of dyes, pigments, inks, and paints (dyes and paints industry), wastewater treatment sludge for the production of organic resins, wastewater treatment sludge for photopolymer materials, plating sludge, slag, sludge, and water treatment sludge for plating tanks in the electroplating industry. The corrosive liquid, washing liquid and sludge produced by acid (alkali) washing, degreasing, descaling and washing process of metal and plastic surfaces, the residue (liquid) and sludge produced by phosphating, polishing and chemical casting of metal and plastic surfaces, electroplating water treatment sludge, waste lead residue and lead acid (sludge) produced by the production of lead (acid) batteries, waste lead residue and water treatment sludge produced by the lead casting industry and the waste water treatment sludge of the organophosphorus compounds wastes. Wastewater treatment sludge, wastewater treatment sludge from organic wastes, wastewater treatment sludge from ether-containing wastes, and wastes from the production, configuration, and use of halogenated organic solvents (water treatment sludge and waste carriers).