Equipment Overview

Closed Circuit Vibrating Fluidized Bed Dryer is a new type of drying (cooling) equipment improved and developed by our factory on the basis of absorbing foreign technology and integrating more than ten years' drying experience, which has been widely used in various industries. Fluidized Bed Drying equipment not only has a good drying function, but also according to the needs of the process to complete the material granulation, cooling, spraying a small amount of liquid, screening and conveying and other processes.

Closed circuit vibrating fluidized bed dryer is an improved hot air convection dryer. When working, the excitation force provided by the vibration motor or other ways, make the material jump forward on the air distribution plate, and at the same time, contact with the hot air fed under the distribution plate for heat and mass transfer. The lower box provides a stable air chamber with certain pressure for the bed. Adjust the induced draft fan to keep the upper part of the bed material in the upper box with micro-negative pressure to maintain a good drying environment and prevent the dust from leaking out. The air distribution board supports the material and makes the hot air distribution uniform.

Closed loop vibration fluidized bed drying equipment explosion risk solution measures

Solve or reduce the organic solvents pesticide raw materials closed loop dryer in the drying process of the safety risks, from the explosion elements of analysis, the selection of inert gases, high flash point solvents to avoid the formation of explosive gases, devices, materials selection of metal conductive materials to eliminate static electricity; to take explosion-proof panels, automatic control and other measures to reduce the explosion of the hazards to people.

(1) organic solvent selection

crystallization of pesticide raw materials, rinsing priority choice of water as a medium, if the API can not use water as a medium should be selected with a high flash point, high lower limit of gas explosion, the explosion limit of narrow solvents, to avoid drying the process of mixed gases can easily reach the explosive concentration, to improve the minimum ignition energy to reduce the risk of explosion.

(2) the use of inert gas nitrogen protection

When selecting flammable and explosive liquids as solvents, drying medium should be selected inert gas nitrogen to effectively avoid the occurrence of an explosion. Nitrogen is safe and reliable, and at the same time, it avoids the oxidization and deterioration of easy-to-oxidize API in the drying process, and improves the quality of the products.

(3) Tail gas treatment equipment and dust bag

Closed-circuit dryer material selection of high-quality stainless steel, air ducts, condensers, fans and other conductive materials such as galvanized steel tubes or stainless steel, dry boiling bed dust bag body material is mostly used fibers, easy to generate static electricity, through the addition of conductive anti-static fibers in the fiber weaving can be uniformly and quickly channeling static electricity, electrostatic electricity will not be accumulated, thereby eliminating the generation of sparks.

(4) Explosion-proof motor, electrical

The induced draft fan and hopper mixing motor use explosion-proof motors, and the on-site control instrumentation adopts explosion-proof measures, and the explosion-proof level meets the explosion-proof requirements of explosive gases and explosive dusts. The electrical control cabinet and the device take isolation measures, and meet the provisions of the relevant distance from the explosion-proof area.

(5) Explosion-proof sheet

In the organic solvent dryer body equipment set explosion-proof plate, explosion-proof plate effectively channel the energy generated when the explosion occurs, to avoid damage to the equipment system. The explosion-proof plate area should be based on the drying material drying medium, organic solvent characteristics, drying temperature and other factors, for organic solvent drying should also consider the occurrence of gas explosions and dust explosion superimposed on the situation.

(6) Anti-static grounding

In the organic solvent drying process, there is a static phenomenon, rapid and uniform discharge of static electricity is essential. In the pipeline, equipment flange selection of special copper braided flange jumper, duct grounding line should be evenly spaced settings, equipment should be reliable equipotential grounding, and interconnected.

(7) Automation and interlocking control

With the development of automation technology, the closed-circuit dryer can be operated by automation program from feeding to drying finished products, recording, alarming, controlling and adjusting the drying medium temperature, drying time, drying air volume and other indexes, and the automation control reduces the number of on-site personnel and effectively protects the safety of the operators. Through the setting of temperature, pressure and online gas detection concentration alarm can be early detection of the existence of safety risks; set up with the heating medium cut off, shutdown interlocking can be dealt with in a timely manner to prevent the expansion of safety hazards.

Closed loop vibration fluidized bed dryer performance characteristics

1, due to the application of vibration, can make the minimum fluidization gas speed, thus can significantly reduce the air demand, and then reduce the dust entrainment, supporting heat source, fan, cyclone separator, etc. can be correspondingly reduced specifications, the cost of complete sets of equipment will be a substantial reduction in the energy-saving effect is remarkable.

2, can easily rely on the adjustment of vibration parameters to change the material retention time in the dryer. Its piston flow operation reduces the requirements of uniformity and regularity of material size, easy to obtain uniform dry products.

3, vibration helps material dispersion, such as selecting the appropriate vibration parameters, the ordinary fluidized bed easy to agglomerate or produce ditch flow of materials may be smooth fluidization and drying.

4、Because there is no intense material return, the air velocity is lower than the ordinary fluidized bed, the material particles damage is small. For in the drying process requirements do not destroy the crystal shape or particle surface brightness requirements of the material *.

5, due to the application of vibration, will produce noise. At the same time, the life of individual parts of the equipment is shorter than other types of dryers.

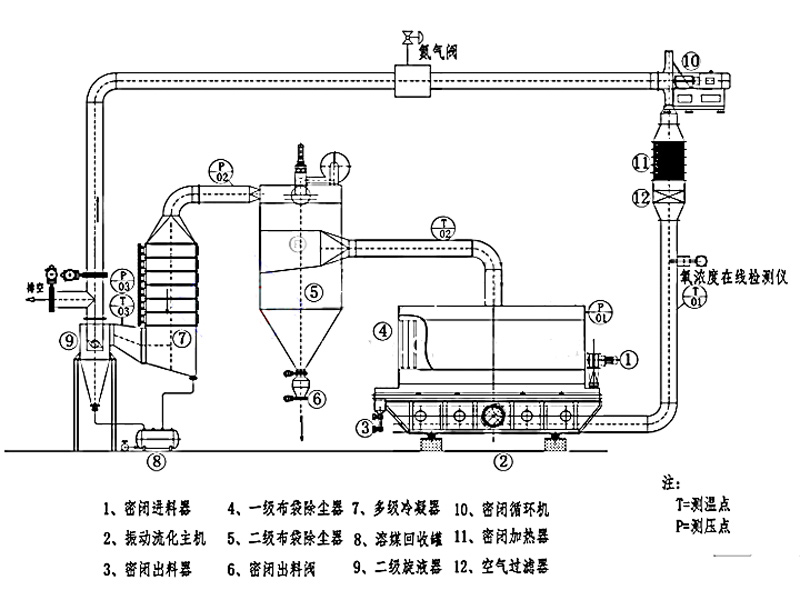

Closed Circuit Vibrating Fluidized Bed Dryer Process Flow Chart