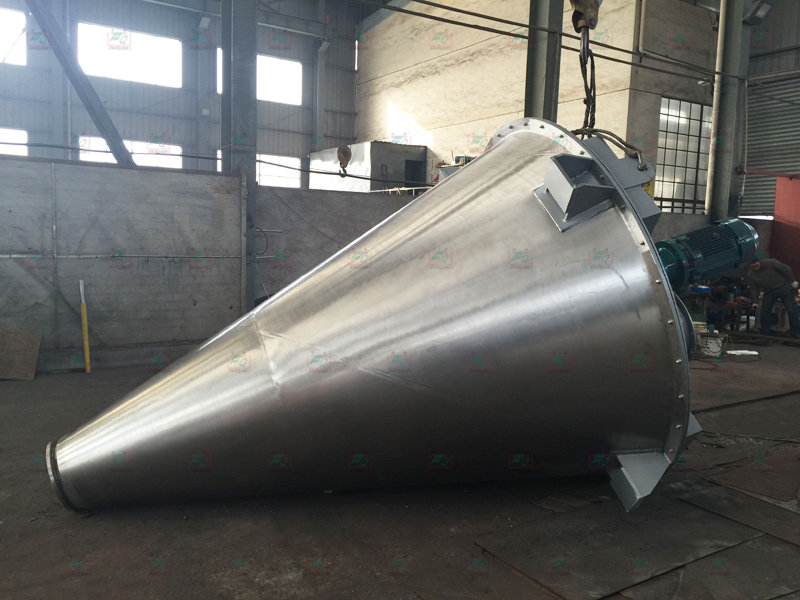

product overview

The composite motion of the material inside the cone is caused by the rotation of the spiral, which mainly produces four forms of motion:

1. Spiral revolution along the wall, causing the material to move in a circular motion along the conical wall;

2. Spiral rotation causes the material to spiral upwards from the bottom of the cone;

3. The combined motion of the spiral's rotation and rotation causes a portion of the material to be absorbed into the spiral cylindrical surface, while being subjected to the centrifugal force of the spiral's rotation, causing a portion of the material in the spiral cylindrical surface to be discharged radially towards the cone;

4. The rising material descends due to its own gravity. The four movements generate convection, shear, and diffusion within the mixer, thereby achieving rapid and uniform mixing.

Equipment features

Can be equipped with flying knives and spray atomization assembly to meet special process requirements.

There are two types of discharge valves: manual and pneumatic.

Special materials can increase the motor power (weight).

Application scope

Applied in chemical, pharmaceutical, pesticide, dye, petroleum, metallurgy, building materials and other industries, including powder to powder (solid solid), powder to liquid (solid-liquid), liquid to liquid (liquid-liquid) mixing, reaction, drying, and cooling.