XSG Series Rotary Flash Drying equipment is driven by hot air tangentially into the bottom of the dryer, forming a strong rotating wind field driven by the stirrer. The paste material enters into the drier by the spiral feeder, and under the strong action of the high-speed rotating stirring paddle, the material is dispersed by the action of impact, friction and shear force.

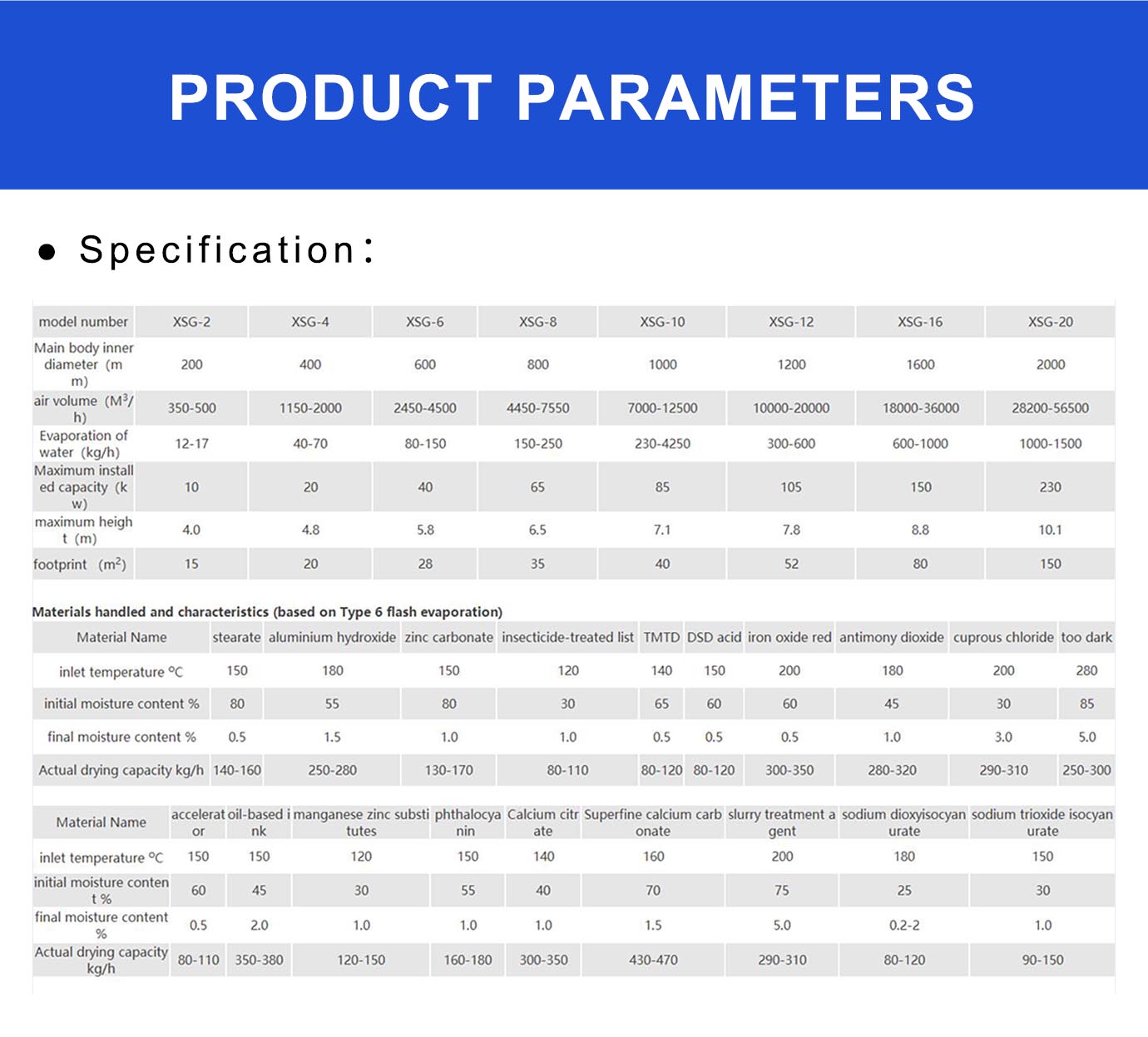

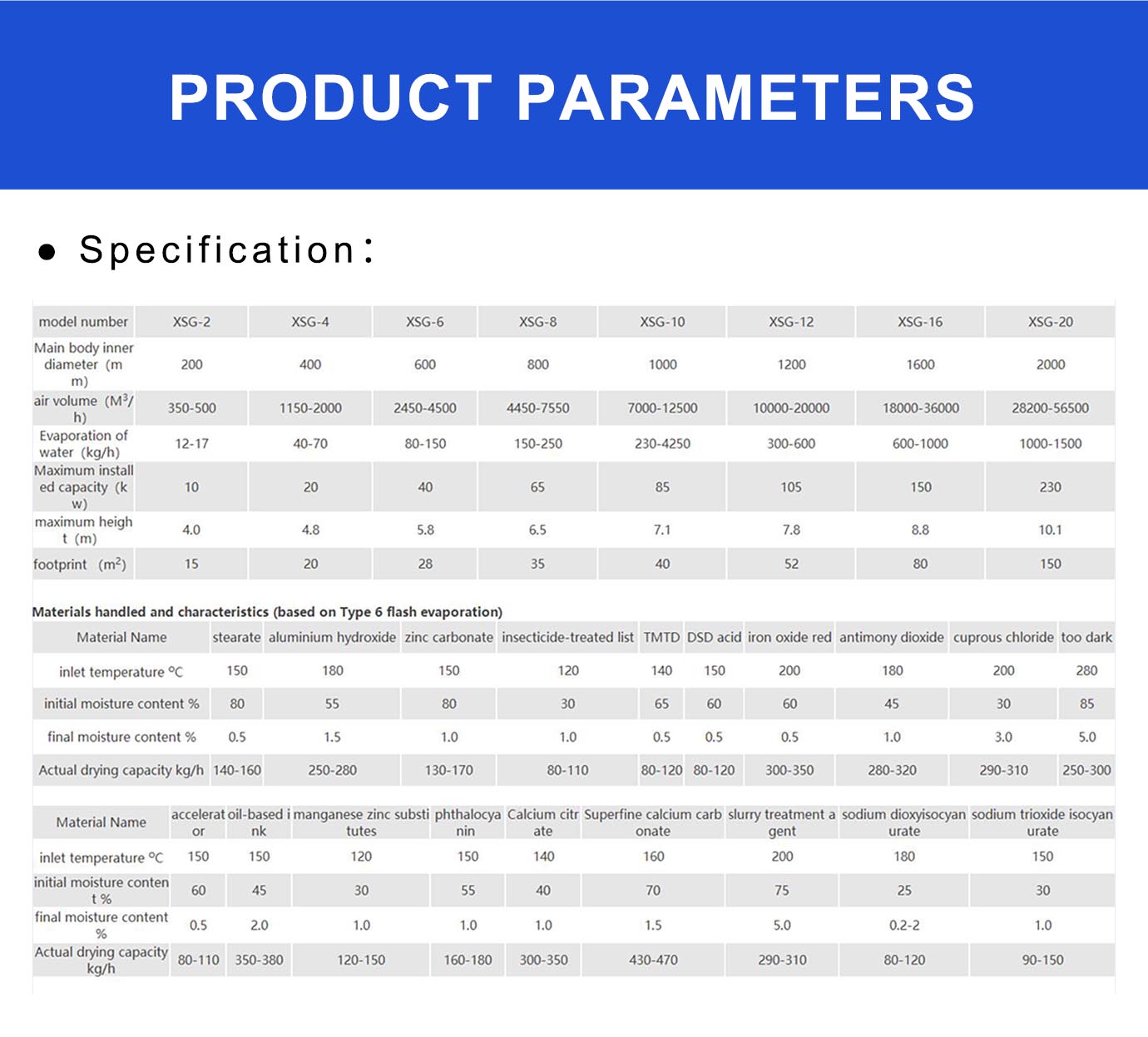

| model number | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

Main body inner diameter(mm)

| 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

air volume(M3/h)

| 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

Evaporation of water(kg/h)

| 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

Maximum installed capacity(kw)

| 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

maximum height(m)

| 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

footprint (m2)

| 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note:

1, moisture evaporation is based on the inlet temperature of 180oC, the outlet temperature of 80oC when the evaporation of water per hour;

2, in addition to the above models can be specially designed for the user;

3, the above installed capacity for the standard package, according to the material of different power packages can be significantly reduced.

Materials handled and characteristics (based on Type 6 flash evaporation)

| Material Name | stearate | aluminium hydroxide | zinc carbonate | insecticide-treated list | TMTD | DSD acid | iron oxide red | antimony dioxide | cuprous chloride | too dark |

| inlet temperature oC | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| initial moisture content % | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| final moisture content % | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacity kg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Material Name | accelerator | oil-based ink | manganese zinc substitutes | phthalocyanin | Calcium citrate | Superfine calcium carbonate | slurry treatment agent | sodium dioxyisocyanurate | sodium trioxide isocyanurate |

| inlet temperature oC | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| initial moisture content % | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| final moisture content % | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| Actual drying capacity kg/h | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Applicable materials.

Organics:Atrazine(pesticide insecticide), lauric acid septum,benzoic acid,organic pigments, etc.

Dyes:anthraquinone,black iron oxide, indigo pigment, butyricacid,various azo dye intermediates.

Inorganic substances:borax,calcium carbonate, hydroxidecopper sulfate, synthetic cryolite and so on.

Foodstuffs:soy protein, gelatinized starch, wine trough, wheatsugar, wheat starch, etc.

Jiangsu Fanqun Drying Firm Equipment Factory Co., Ltd. products sell well all over the country, exported to the United States, Japan and Southeast Asian countries, welcomed by domestic and foreign users, the market reputation is excellent, but also China's drying equipment in the professional manufacturer of larger, more varieties of better quality of enterprises.

Complete scientific and quality system Professional technical team and superb technology Sophisticated production equipment

The company has large laser cutting machine, large water cutting machine, large plasma cutting machine, large automatic welding machine, non-destructive testing, mass spectrometer planer, bending machine, shearing machine and other high-end manufacturing and processing and inspection equipment.

Perfect after-sales service system

Pre-sales services :To provide you with project design, process design, suitable for your machine and equipment selection program development, according to your special needs, design and manufacture of products, for your training of technical operators.

Services during sale :Accompany you through the acceptance of the equipment and assist in the development of construction plans and detailed procedures.

After-sales service :The company sends technicians to the site to guide equipment installation commissioning site and training operators.

flash drying machine,flash dryer manufacturers,flash dryer,flash drying equipment